MFaulks wrote:.

Oooo nice flames JohnI know I said tune for maximum smoke, but ....

Yes, just need to get it directed in the opposite direction then it might do some useful work.

Moderators: eastlmark, phildini, BIG_MVS, Alpineandy, Test Moderator

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

MFaulks wrote:.

Oooo nice flames JohnI know I said tune for maximum smoke, but ....

Non Member

2120

Sun Dec 02, 2007 6:19 pm

Jersey C.I.

johnb wrote:.........and not timing chain related.

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

JohnC wrote: ........ the term...."rocking valves" or "valves on the rock"..... are you "au fait" with these ?

John

johnb wrote:If you eventually decide that the timing chains need checking, I have a method which is pretty accurate that does not involve removing the timing chain covers and all that that involves.....

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

MFaulks wrote:.

then loosen the distributor and advance it a bunch, sounds like you are well off and retarded .

Martin

Non Member

2120

Sun Dec 02, 2007 6:19 pm

Jersey C.I.

johnb wrote:My understanding of rocking valves is when the piston is at TDC and the exhaust valve is almost closing and the inlet valve has just started to open, i.e. the overlap point when both valves are slightly open.

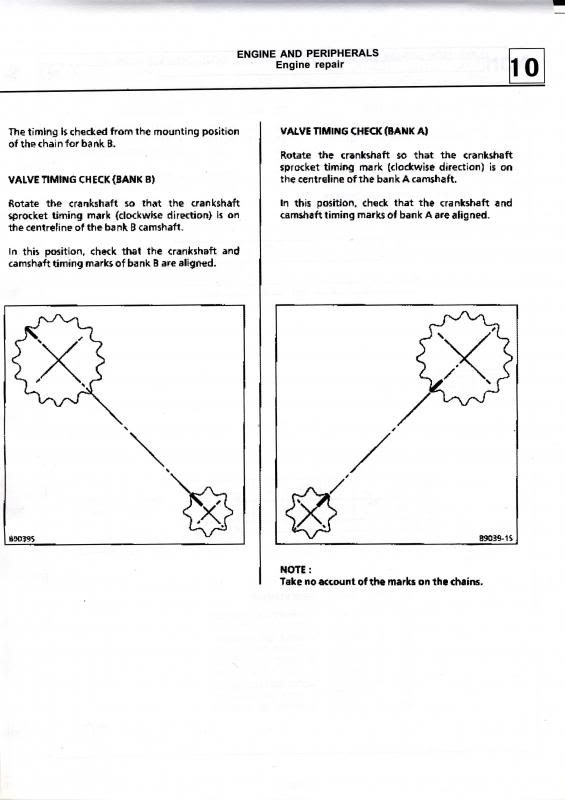

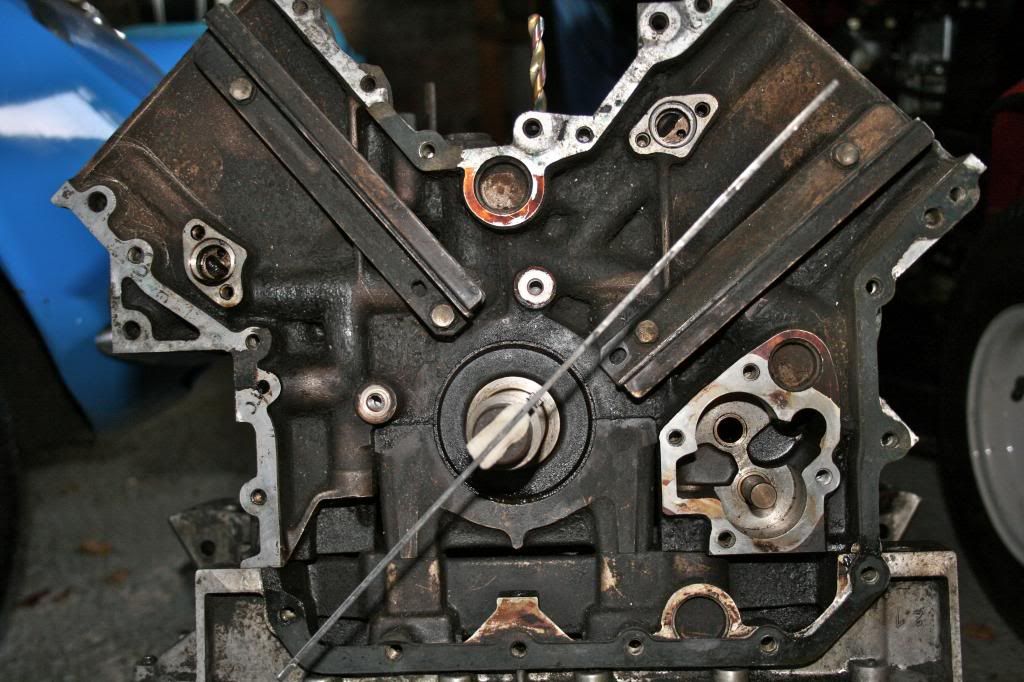

According to the books that I have, you set the crankshaft at TDC and then the 1,2,3 camshaft in the valve rocking position for cylinder 1 and fit the chain with its marks lined up on the crank sprocket and the cam sprocket. Then rotate the crankshaft 150 degrees clockwise and position 4,5,6 camshaft with cylinder 6 valves rocking and then fit the chain to the crank sprocket and cam sprocket marks.

To set the distributor position, following the book procedures, needs both cylinder 1 valves closed, at TDC, i.e. on the firing stroke. This position being 360 degrees from the cylinder 1 valve rocking position. The distributor rotor 'contact' should then be opposite the mark on the distributor base and the cylinder 1 contact in the distributor cap.

To find TDC on the firing stroke of cylinder 1 again, I've been cranking the engine on the remote start with the ignition off, cylinder 1 spark plug out and stopping the cranking just after I feel the pressure coming out of the plug hole. The timing mark on the crank pulley then being close to TDC.

I don't know this method. I can only guess that it has something to do with looking at rocker positions relative to the crank timing mark positions.

If it's not too much trouble to provide the procedure then it can only help in verifying, or otherwise, what I've done.

I'm trying to avoid removing the rocker covers because I used sealant on the gasket faces when I fitted the covers and if they're removed the gaskets will probably be useless afterwards and they don't seem to be easy to obtain.

Non Member

1552

Sun Sep 28, 2008 4:25 pm

Non Member

1552

Sun Sep 28, 2008 4:25 pm

johnb wrote:MFaulks wrote:.

then loosen the distributor and advance it a bunch, sounds like you are well off and retarded .

Martin

Just a thought Martin. If you recall, on your recommendation, I fitted GTA camshafts on this engine build. The book timing for the A310 engine is 10 degrees BTDC. I believe the GTA timing is 15 degrees BTDC. With you saying it sounds retarded, should it now be timed for the GTA setting, if 15 degrees is correct, or some other advance number?

Non Member

2120

Sun Dec 02, 2007 6:19 pm

Jersey C.I.

MFaulks wrote:.JohnC - please describe your method, all good pointers are useful, and have you used it to time cams in from scratch, or just on existing assemblies?

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

JohnC wrote:I am sure there are others who know these PRV engines better than me, so I expect some corrections along the way.

Non Member

2120

Sun Dec 02, 2007 6:19 pm

Jersey C.I.

johnb wrote:JohnC, your setting method. I think I can understand the logic your approach but am I correct in thinking that yours is an offset crankpins, even fire engine?

The reason I ask is because my A310 engine is equidistant crankpins, odd fire type. With this engine, if cylinder 5 rockers are rocking this is 30 degrees past TDC. The firing order is the same as you quote: 1,6,3,5,2,4 so for my engine this gives 0 + 150 + 90 + 150 (= 390, i.e 30 ATDC) degrees for cylinder 5 (cyl. 1 being the first zero).

Looking at the PRV manual on the website, I agree that the procedure is the same as in my manuals and pages 83 & 84 would apply to the A310. Pages 85 & 86 I think are only applicable to the even fire engine.

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

JohnC wrote: but page 86, I am sure would apply to both types as the chains and cogs can only rotate with a 2 to 1 reduction to the cam cogs for any engine,

John

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

johnb wrote:According to the books that I have, you set the crankshaft at TDC and then the 1,2,3 camshaft in the valve rocking position for cylinder 1 and fit the chain with its marks lined up on the crank sprocket and the cam sprocket. Then rotate the crankshaft 150 degrees clockwise and position 4,5,6 camshaft with cylinder 6 valves rocking and then fit the chain to the crank sprocket and cam sprocket marks.

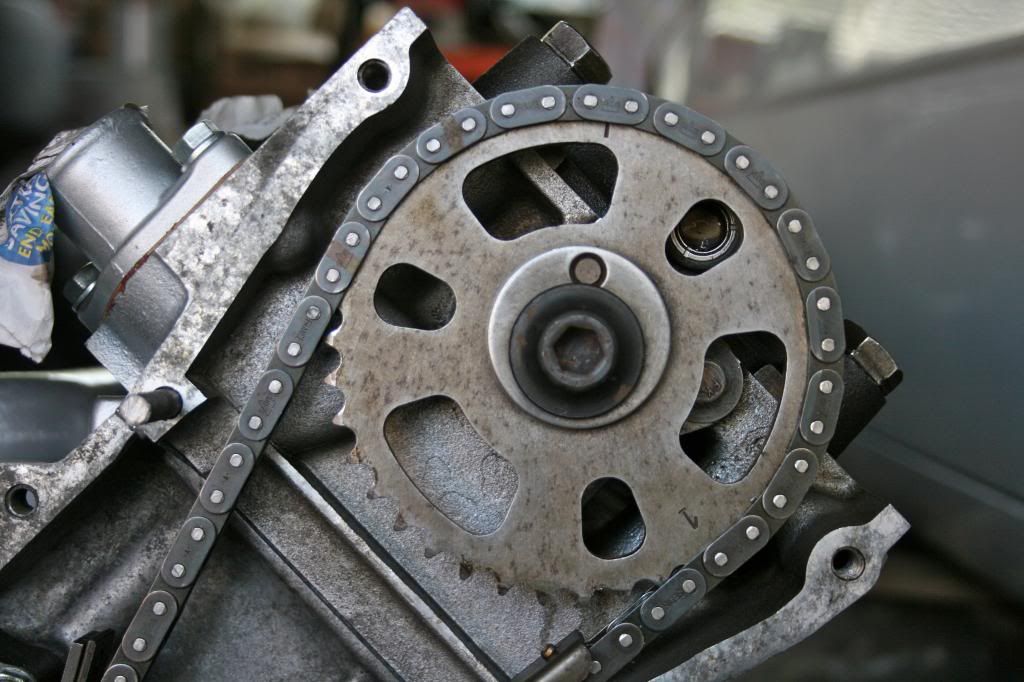

johnC wrote:I have not come across this way of cam shaft timing, and I have to say I don't think it is a very accurate way to do this task. (First barrage here please)...... Now I have assumed that the 6cyl 310 PRV is the same as the GTA PRV but with a different ignition system. (Second barrage...) and as such I have looked at the process of setting the cam shafts the GTA way, and it does seem to be a bit more sophisticated and accurate way.

If you go to the Technical Help section of this site, Click on "PRV Engine" and download the "GTA & 610 Engine manual" English version, scroll down to pages 83 through 86, the process is certainly different. You may have to read it a few times to make sense of the different way to do the B bank but I think pages 83 & 84 are the right ones for the 310, but page 86 refers to both Bank B types and I have to assume that page 86 shows the final test of the process (Third barrage...)

Unfortunately your pic of the timing chains does not show up the timing marks on the gear wheels sufficiently to comment further.

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

MFaulks wrote:.

loosen the distributor and advance it a bunch, sounds like you are well off and retarded .

Martin

JohnC wrote:.

does your manual show which coil king lead goes to each of the distributor king lead inputs, and which coil 12v goes to each of the set of points..... as I am sure you know, any cross wiring in this area will lead to incorrect timing.

johnb wrote:To find TDC on the firing stroke of cylinder 1 again, I've been cranking the engine on the remote start with the ignition off, cylinder 1 spark plug out and stopping the cranking just after I feel the pressure coming out of the plug hole. The timing mark on the crank pulley then being close to TDC

JohnC wrote:I would be doing all of these tests with the plugs removed and a socket and ratchet lever on the crank pulley, that way you can back off if necessary and come back to a very accurate position of, say, TDC. and you won't have to contend with the compressions with the plugs removed

MFaulks wrote:if you need to remove the rocker covers, just carefully seperate the gasket from your silicone bond with a 10thou feeler or there abouts

MFaulks wrote:I wasn't talking a few degrees more like a big handful up to the distributor180 out scenario. Easy check, bring to TDC firing on number 1 (both rockers rocking with clearance, valves closed), plug out, ignition on, with your current dizzy position marked. Then manually swing the distributor back and forth from your original install position mark. Whilst you do this the spark plug no. 1 should be firing, if not then you have the phasing wrong. The other is check your condenser are good, but I think this is more likely to be firing phasing. This is a nice physical check that you can safely and positively verify each plug firing phasing.

MFaulks wrote:Is the static timing set / verified with he vacuum disconnected?

Non Member

1552

Sun Sep 28, 2008 4:25 pm

Non Member

858

Wed Sep 13, 2006 6:57 pm

Cheshire

MFaulks wrote:.

the only thing I would have done is swung the dizzy back and forth around the firing point than directly openning the points myself........ another thing you can do if you are getting a bit of plug wetting with excess cranking etc, is pull the plug leads off the plug connection ie have them pulled back a little so it arcs inside the lead to the plug contact as well.....

Users browsing this forum: No registered users and 130 guests