.

Well hello peeps, I’m back at it again having been down the work cave for a while… So I have been picking up with various things again. Cams and rocker story I will pick up again soon, but thought you might enjoy the things that I have tried that didn’t work…

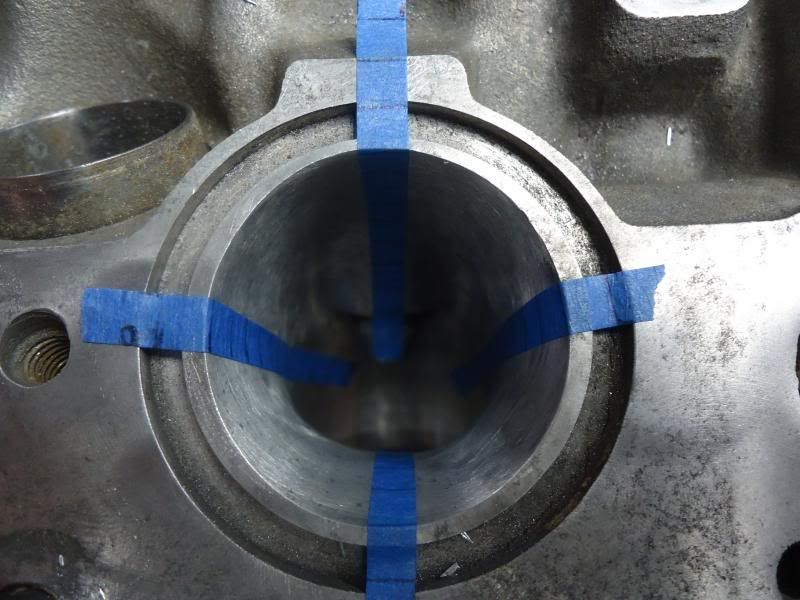

But first the damage to my w/shop buddies engine post the dropped exhaust valve thanks to the failed spring picture a couple of pages back. As below, actually not too bad, and opted not to strip the bottom end as the damage was light, the valve guide wasn’t hammered, and the valve was only slightly bent, which obviously went in the bin! I have to say there is definitely a satisfaction in throwing PRV engine parts in the bin that I have not found with other engines! I some how keep all my old Fiat / Lancia engine parts and feel like treasures… but there is a story behind that too… laugh!

Right here goes, in all its ugly history:

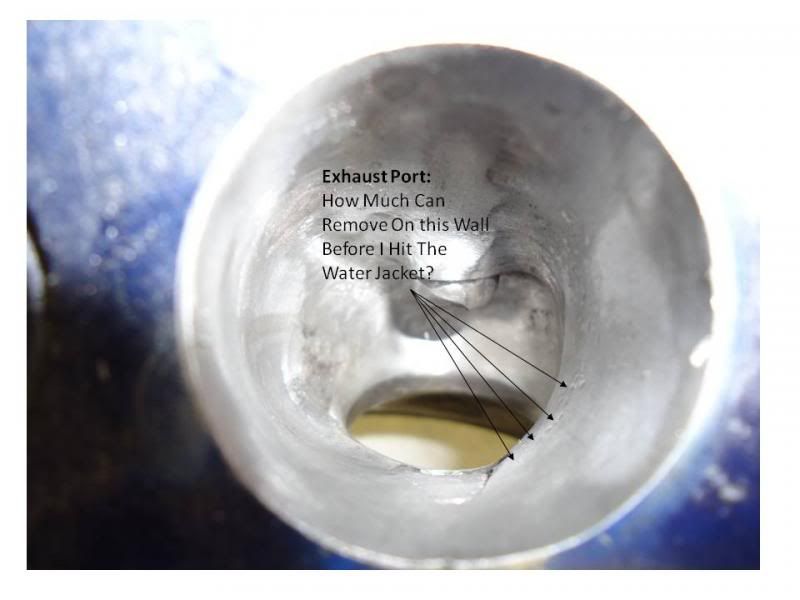

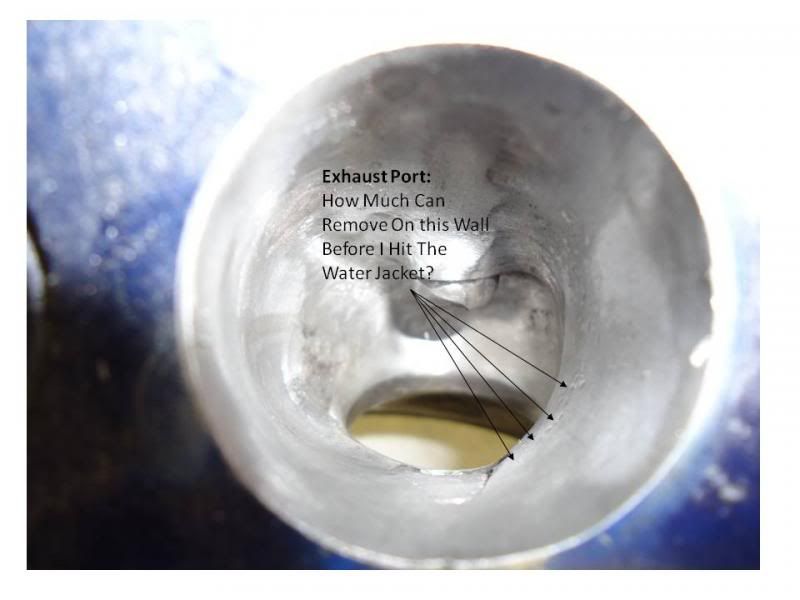

Whilst the heads were off, and I had to look at the seats anyway, especially on the hammered exhaust valve, I then checked them out. I found that I was getting seat distortion with heat and loss of seal. I had sunk the seats in a big throat to gain flow without going to a big valve in this set of heads for an experiment ie the larger valve seat, big port with a small valve in the seat. Flowed great as little restriction when it was lifted up out of the way fast, and I had paired up with fast ramp cams to match, but… real life running with real heat loads and stresses other things happen, so to gain the knowledge you have to pay the money and test it… Well I did, and I can say don’t bother, as it doesn’t last…

The coefficient of discharge is great, hence the flow, but as I say it didn’t maintain seal, so you lose VE when it’s hot. Hence, having cut the heads and sunk the cost, I had to fins a way to get it to seal and play with valve head diameters to not completely lose what I had originally set out to gain.. So this is where I got to, and the heads are now back home and happy on the block.

Original size 39mm exhaust valve dropped back in to check seating and then test coeff of discharge, and then worked back from there after a few quick look-see tests to what is seen further down.

So I played with a compromise, valve seat mods and exhaust valve machined to match the detail:

And ended up with this – yum yum…

.

.

.

.